Melt granulation machine

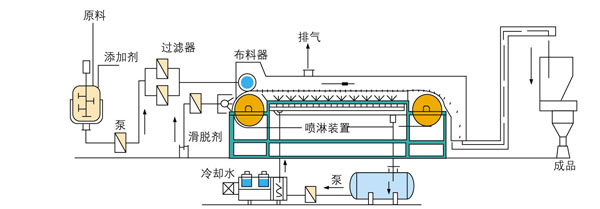

Melt granulation machine is the use of low melting point of the material, according to scope of viscosity of the molten state through a special feeding device will melt evenly on the bottom of its uniform movement of the strip, continuous spray apparatus set at the bottom of the strip under cooling effect, so that the material transport, shift operation process has been cooled and solidified, the packaging, so as to achieve a type of granulation purposes.

Product Brief

Melt granulation machine is the use of low melting point of the material, according to scope of viscosity of the molten state through a special feeding device will melt evenly on the bottom of its uniform movement of the strip, continuous spray apparatus set at the bottom of the strip under cooling effect, so that the material transport, shift operation process has been cooled and solidified, the packaging, so as to achieve a type of granulation purposes.

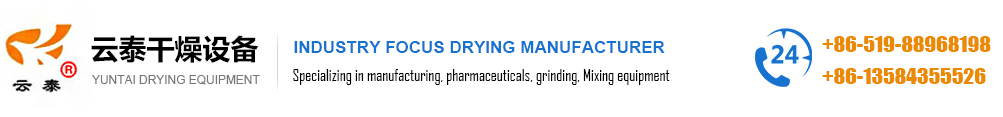

Melt granulation machine) is a new type (meltable) into a type granulation machine. Work by the cooling liquid through the delivery becomes solid, the melting point range of 50 ℃ -300 ℃ material may granulation into type. No dust, improve the production environment; and a certain economic value (energy saving, economical packaging containers) product replacement fast, pelletized product beautiful, even almost half ball type granular, no heat stress; granular product is both easy packing, transport, storage , and user-friendly measuring, mixing or remelting, continuous production. Fed from the packaging, reduce manual labor, with stepless adjustable flow, easy to operate. Widely used in petroleum, chemical and other industries. A machine-made strips, diced, sheet; toxic materials can be used for closed-end.

Features

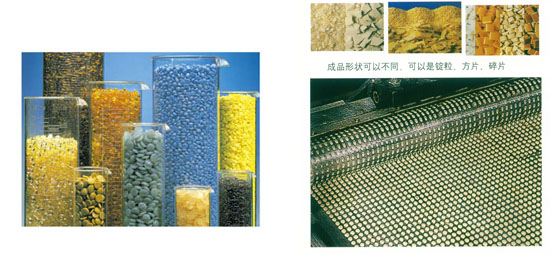

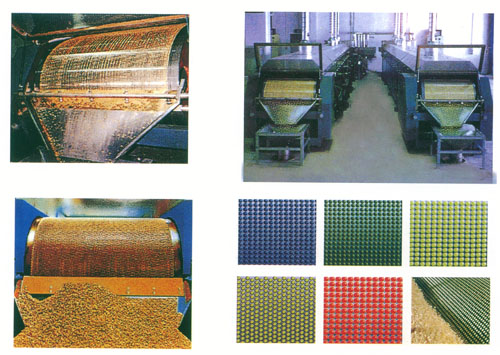

Melt granulation machine is a new type (meltable) into a type granulation machine. A thin strip heat and atomized spray cooling the molten liquid into a rapid curing type, the use of stand-alone rotating shell. So easy maintenance, wear very little, and high productivity. Handling and quick replacement product. And falling into a mold and strip machine type synchronous operation it is possible high-speed production of ingots uniform grain, improve productivity and increase production profits. And can eliminate dust, improve the environment, significantly expanded the range of viscosity. The product is an economical and reliable production process, the ingot can be processed grain Φ4-12mm these products is very uniform, hemispherical, strip and sheet, stable, non-thermal stress are very high quality and purity

Production structure

1. processed products melting point (freezing point), temperature and viscosity of different materials cooling effect, to choose the delivery speed and the speed of the nose, so as not to affect the production capacity and granular quality.

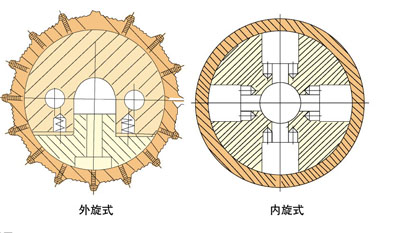

The aircraft from liquid to solid particulate, mainly through the granulation die granulation, using a rotary continuous, fixed by spraying water cooling type, complete with stainless steel cooling, transporting, packaging is generally more than 1-3 kg / cm2.

The processed products of melting point (freezing point), temperature and viscosity of different materials cooling effect, to choose the delivery speed and the speed of the nose, so as not to affect the production capacity and granular quality.

The aircraft from liquid to solid particulate, mainly through the granulation die granulation, using a rotary continuous, fixed by spraying water cooling type, complete with stainless steel cooling, transporting, packaging is generally more than 1-3 kg / cm2.

Technical requirements material must not be filtered solid impurities into the granulation head, otherwise it will cause head wear or blockage of granulation quality.

Temperature control should be based on the melting temperature to be, can not change the temperature insulation requirements. More than ± 3 ℃. The cooling system should be added to the filter, the cooling water temperature is generally between 5 ℃ -25 ℃ (low temperature, to type fast, granular, high yield).

Advanced cloth set of process equipment

Technical Parameters

|

Model

|

RL60-A

|

RL60-B

|

RL60-C

|

RL60-D

|

RL120-A

|

RL120-B

|

RL120-C

|

RL120-D

|

|

The effective heat transfer area (m)

|

2.6

|

3.6

|

4.6

|

5.3

|

7.3

|

9.3

|

10.8

|

16.6

|

|

Master / slave motor power (kw)

|

1.5 / 0.75

|

1.5 / 0.75

|

1.5 / 1.1

|

1.5 / 1.1

|

3 / 1.5

|

3 / 1.5

|

3 / 1.5

|

4 / 2.2

|

|

Dimensions (mm)

|

5600 × 1200

× 1800

|

7200 × 1200

× 1800

|

8800 × 1200

× 1800

|

10050 × 1200

× 1800

|

7200 × 1700

× 1800

|

8800 × 1700

× 1800

|

10050 × 1700

× 1800

|

14800 × 1700

× 1800

|

|

Production capacity (kg / h)

|

80-100

|

100-150

|

120-180

|

150-250

|

300-380

|

360-420

|

380-500

|

500-800

|

|

Total weight (kg)

|

1360

|

1580

|

1880

|

2060

|

2380

|

2590

|

2830

|

4210

|

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us