Product Brief

JYG series paddle drier is an internal device settings stirring paddle, wet substance under Section paddle agitation, full contact with the hot surface and the heat carrier, so as to achieve the purpose of drying low-speed stirring dryer. Structure is generally horizontal, axis or dual-axis. JYG series paddle drier into hot air and conduction. I.e., hot air drying of the material is in contact with each other by means of a heat carrier (eg hot air) and dried with, the heat conduction in contact with each other but not the carrier material was dried in direct contact with the hot surface of the material. Conduction advantage is that the material can not easily be contaminated, displacement of small, high thermal efficiency, the volume is relatively small, is conducive to energy conservation and the prevention of air pollution.

JYG series paddle drier hollow shaft densely arranged hollow wedge type paddle, heat medium through the hollow axial warp paddle. A large heat transfer area per unit volume of the effective heat medium temperature from -40 ~ 320 ° C, can be water vapor, or liquids type: such as hot water, oil and the like. Indirect spread heating, no air to carry away the heat, the heat was used to heat the material, the heat loss is only the heat insulation layer to the environment through the body. Wedge-shaped paddle heat transfer surface having a self-cleaning material particles relative movement of the wedge surfaces to produce wash effect, can wash away the surface of the wedge-shaped attachments, commissioning has maintained a clean heat transfer surfaces.

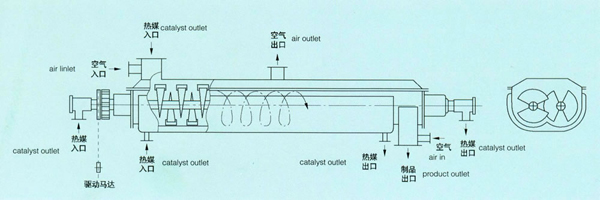

working principle

W-shaped housing JYG series paddle drier by the two to four paddle shaft intermeshing with a jacket, docking station and transmission parts, the entire drying process the material in a closed state, an organic vapors and gas odors Handled sent a confined atmosphere exhaust means to avoid environmental pollution.

Hollow shaft paddle slowly rotating drive in the drive, the material from the feed inlet into the machine through the slow rotation of the hollow shaft paddle delivered to the discharge port. Materials during transport by both hollow and paddle jacket heating and drying. Since the wedge-shaped hollow paddle rotation when the material is alternately compressed (wedge ramp at) and expansion (in the wedge-shaped gap at), thus making the heat transfer surface material movement intense, but also to strengthen the self-cleaning heat transfer surface effect, thus greatly improving the heat transfer coefficient. Medium heat for drying can be steam, hot water or thermal oil. Heat medium into the hollow shaft and paddle through the rotary joint. When the heat medium to the cooling water, the machine is ideal for powder cooling equipment.

JYG series paddle drier steam, hot water or thermal oil as the heating medium, shaft with a hot medium import and export of the swivel. Heating medium is divided into two, respectively, into the drier housing jacket and a paddle shaft cavity, and the body of the paddle shaft while heating, conduction heating, and the material is heated and dried.The dried material from the screw feeder quantitatively continuously fed drier charging port, behind the material into the device by rotating paddle of the material flipping, stirring constantly updated heated interface with the body of the contact and the paddle is fully heated, so surface moisture evaporation material contained. At the same time, the material to the discharge port with the transport direction of rotation into a spiral track paddle shaft, stirring was continued during transport, the sludge seeping water continues to evaporate. Finally, uniform drying qualified products from the discharge port.

Features

▲ The equipment is compact, small Floor area, high thermal conductivity, excellent thermal efficiency, generally 80% to 90% energy saving type equipment.

▲ JYG series paddle drier low speed for crushing granular and sheet material is small.

▲ JYG series paddle drier wide adaptability of materials, operating flexibility, residence time from minutes to hours, adjustable.

▲ The attachment is simple, less investment. Low operating costs.

▲ a machine can be used for drying, cooling, gas recovery, the reaction was heated (pre-sterilization) and other technology operations.

Schematic

Adaptation of raw materials

Drying plastic, resin products, inorganic chemicals, fertilizers, feed, food, chemical fiber, dyes, starch, drain sludge and other products. Such as: vinyl chloride resin, nylon, polyethylene, polypropylene, starch, sodium chloride, sugar, iron oxide, feldspar, soda powder, soda ash, and other particulate paste Section.

Technical Parameters

| Item \ Model |

JYS-10 |

JYS-16 |

JYS-24 |

JYS-32 |

JYS-60 |

JYS-100 |

| Heating area m2 |

10 |

16 |

24 |

32 |

60 |

100 |

| The evaporation capacity kg · H 2 O / h |

40 |

65 |

96 |

128 |

250 |

400 |

| Speed rpm |

2.5-25 |

| Drive power kw |

5.5 |

7.5 |

7.5 |

11 |

15 |

15 |

| Dimensions m |

4.5 × 1.5 × 1.8 |

5.5 × 1.5 × 2 |

6.1 × 1.5 × 2 |

7.1 × 1.6 × 2.1 |

8.1 × 1.7 × 2.2 |

9.1 × 1.9 × 2.5 |

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us